High Efficiency Starch Desand Machine , Corn Starch Fiber Sand Remove Machinefunction gtElInit() {var lib = new google.translate.TranslateService();lib.translatePage('en', 'th', function () {});}

รายละเอียดสินค้า:

| Place of Origin: | Zhengzhou City,China |

| ชื่อแบรนด์: | JINGHUA |

| ได้รับการรับรอง: | CE |

| Model Number: | CSX22.5-1 CSX22.5-2 CSX22.5-3 |

การชำระเงิน:

| จำนวนสั่งซื้อขั้นต่ำ: | 1 ชุด |

|---|---|

| ราคา: | สามารถต่อรองได้ |

| Delivery Time: | 5-14 work days after recevied pre-payment |

| Payment Terms: | L/C, D/P, T/T |

| สามารถในการผลิต: | 10 ชุด/เดือน |

|

ข้อมูลรายละเอียด |

|||

| Application: | Corn starch desander | Material: | 304 or nylon |

|---|---|---|---|

| Sand removal rate: | 98% | พลังงาน: | ติดตั้งระบบไฟฟ้า |

| เงื่อนไข: | ใหม่ | การติดตั้ง: | ใช่ |

| Voltage: | 220V or 380V | การบรรจุ: | กรณีไม้ |

| เน้น: | เครื่องแป้งข้าวโพด,เครื่องประมวลผลแป้งข้าวโพด |

||

รายละเอียดสินค้า

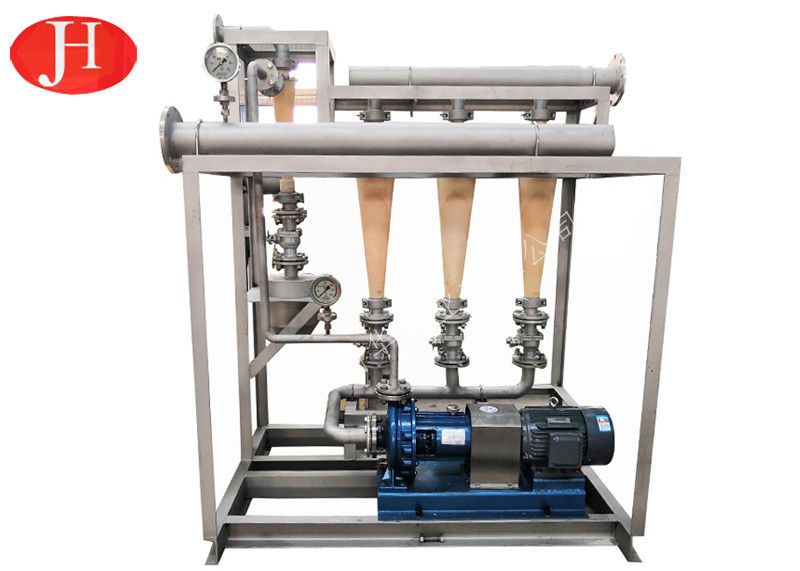

High Efficiency Desand Machine Corn Starch Fiber Sand Remove Machine

Product Description

The desander mainly uses the principle of centrifugal separation to remove the sand of sweet potato starch, cassava starch, wheat starch and corn starch.

Main Features of Desand Machine

1. There are a variety of models, according to the needs of customers to provide the best solution.

2. Using high technology, the removal rate of starch is greater than 98%.

3. Reasonable structure of desand machine, more conducive to water saving.

Main Technical Parameters

| Model | Material | Capacity(㎥/h) | Feed Pressure(Mpa) | Sand Removal Rate(%) |

| CSX15-Ⅰ | 304 or nylon | 30-40 | 0.2-0.3 | ≥98 |

| CSX15-Ⅱ | 304 or nylon | 60-75 | 0.2-0.3 | ≥98 |

| CSX15-Ⅲ | 304 or nylon | 105-125 | 0.2-0.3 | ≥98 |

| CSX20-Ⅰ | 304 or nylon | 130-150 | 0.2-0.3 | ≥98 |

| CSX20-Ⅱ | 304 or nylon | 170-190 | 0.3-0.4 | ≥98 |

| CSX20-Ⅲ | 304 or nylon | 230-250 | 0.3-0.4 | ≥98 |

| CSX22.5-Ⅰ | 304 or nylon | 300-330 | 0.3-0.4 | ≥98 |

| CSX22.5-Ⅱ | 304 or nylon | 440-470 | 0.3-0.4 | ≥98 |

| CSX22.5-Ⅲ | 304 or nylon | 590-630 | 0.3-0.4 | ≥98 |

Product Show

Our Service Pre-sale service ![]()

![]()

![]()

1. Introducing detail features and application of the products to customer.

2. Selecting economical and practical machines for customer.

3. Providing operation data of the related machine.

4. Providing means of trial performance for customer.

5. Flow chart and factory designing layout .

Sale service

1. Recommending engineering conditions required for installation of the machine.

2. Communicating the manufacturing progress of machines with customer in time.

3. Project planning and design services.

After-sale service

1. Training of equipment maintenance and operating personally.

2. Installation and commissioning of equipment until everything is functional.

3. One year warranty and providing long-term maintenance service and spare parts.

4. Giving technical support to customer for developing new product.

5. Engineers available to serve machinery overseas.